Carlow Brewing Company also known as O’Hara’s Brewery, is a family-owned craft brewery located in County Carlow, Ireland. The brewery has a strong commitment to sustainability and has recently installed a new effluent treatment plant to further reduce its environmental impact.

What is Brewery Effluent Treatment?

Brewery effluent is the wastewater generated during the brewing process. This wastewater contains various organic and inorganic pollutants such as yeast, hops, and malt, as well as cleaning agents, chemicals, and other substances used in the brewing process.

Beweries are known for producing large amounts of effluent, which is why it is essential for them to invest in effluent treatment systems. By doing so, breweries can reduce their environmental impact and ensure that their operations are sustainable.

Project Background

MSA Environmental worked with Watertecnik to produce a comprehensive design that was successful following a tendering exercise. We continued to innovate and develop the plant and building began on site in early 2022.

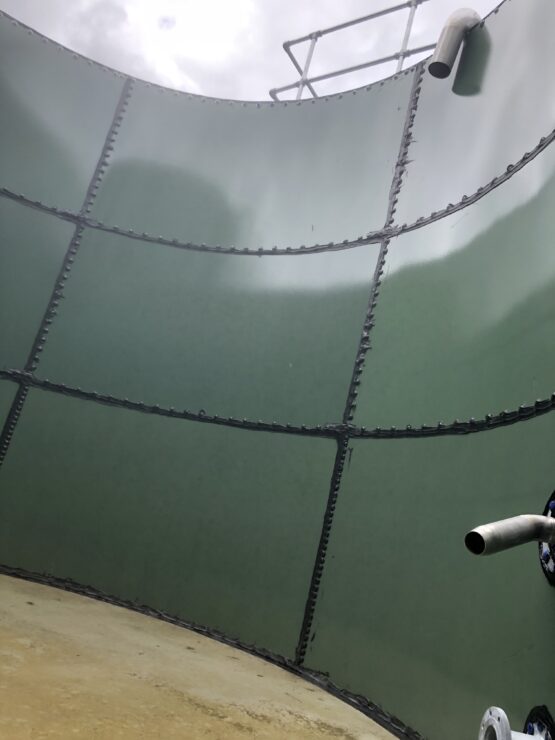

The new treatment plant uses a combination of physio-chemical and biological processes to remove pollutants from the brewery’s effluent. The plant includes a dissolved air flotation system, which separates solids from the wastewater, and an activated sludge system. The treated wastewater is then discharged to sewer, where it meets agreed environmental standards.

Brewery Effluent Treatment Scope

The design included a number of key plant items, including:

- New Crude Effluent Sumps

- Crude Effluent Screening

- New Balance Tank including aeration

- Primary Dissolved Air Flotation (DAF)

- Aeration Tank complete with aeration system

- BioDAF solids Separation system including including chemical makeup and dosing system

- Sludge Storage

- Final Effluent Monitoring